CJ-3A, CJV-35/U, and M38 Fuel pump

information and rebuilding.

Description of operation

Helpful information

Testing

Removal and installation

Part numbers

Special tool for pump

rebuilding

CJ-3A, CJV-35/U pump rebuilding

M38 pump rebuilding

Modification of M38 Fuel Pump

Description

of operation

These mechanical fuel pumps are the diaphragm type, driven from an

eccentric on the engine camshaft. As the eccentric moves the rocker arm

the diaphragm is pulled against the pressure of the diaphragm spring. A

vacuum is formed in the fuel chamber and fuel is drawn in through the

inlet check valve(s) from the fuel tank. As the eccentric rotates the

pressure on the rocker arm is released and the diaphragm spring pushes

the diaphragm forcing fuel out to the carburetor through the outlet

check valve(s). When the carburetor does not require fuel, the pressure

in the fuel chamber holds the diaphragm and diaphragm spring in

compression and fuel does not flow. The fuel pump output pressure is

proportional to the force of the diaphragm spring.

The vacuum booster section of the fuel pump operates in the same

fashion as the fuel pump. Its purpose is to provide vacuum for

windshield wiper operation under higher throttle conditions where

engine manifold vacuum is too low for satisfactory wiper operation.

When engine manifold vacuum is greater than

that created by the pump, the stronger manifold vacuum pulls the

diaphragm into the air chamber against spring pressure and the pump

does not pump.

Helpful

information

The CJ-3A, CJV-35/U and M38 utilize spacers between the fuel

pump

and the engine block. Over the years these spacers are often removed

for various reasons. The CJ-2A style fuel pump is often retrofitted to

these vehicles due to its lower cost. This is a fuel pump only, without

the vacuum booster section. It does not require a spacer for proper

operation. Lack of a

spacer on the original CJ-3A, CJV-35/U and M38 fuel pumps can cause

excessive fuel pressure. Fuel pressure can be lowered slightly by

adding extra gaskets between the fuel pump and engine block.

Old stock pumps and rebuild kits. Diaphragms stretch and deteriorate

with age. Old diaphragms are not made to withstand

today's fuel compositions. It is best to use modern replacement

diaphragms.

Venting of the fuel pump. CJ-3A fuel pumps have a vent in the body of

the fuel pump, as most fuel pumps do. Since the CJV-35/U was designed

to operate underwater, the vent is eliminated as well as the upper oil

seal. M38s before serial number 53262 originally had a plug in the body

center threaded hole. This is where a vent would normally be located.

Apparently there were problems with this

arrangement since many vehicles were retrofitted with various vents

here. The service manual also has a modification procedure to be

performed on the pumps. M38s after serial number 53262 had a different

underwater ventilation system and the fuel pump was vented at the

center of the body. See M38

Underwater Ventilation System for more information.

Testing

Caution Gasoline and gasoline vapors are highly flammable. A fire could

occur if an ignition source is present. Have a dry chemical (Class B)

fire extinguisher nearby.

Fuel pump pressure test. Connect a fuel pressure gauge to the fuel

pump output line. Run the engine at a fast idle and note the pressure.

CJ3A and CJV-35/U fuel pressure should be 2-1/2 to 3-3/4psi and M38

fuel pressure should be 4 to 5-1/4 psi.

Fuel pump capacity test. Connect a hose to the fuel pump output and

place in a

container. Start the engine and run at idle speed. It should take 20-30

seconds to pump 1 pint of gasoline into the container.

Vacuum pump test. Disconnect the vacuum line going to the intake

manifold and plug the manifold side of the line or fitting. With the

engine

idling, if the windshield wipers operate even at a slow speed, the

vacuum pump is satisfactory. With the manifold line still disconnected,

attach a vacuum gauge to the line that goes to the wipers. Vacuum

should be about 10 in. of vacuum at a fast idle.

Problem and possible cause

Low fuel pressure - Mechanical wear, Stuck or leaking valves, Leaking

diaphragm,

Fuel

supply

problem,. Dirty filter screen, Suction side air leak

Low fuel volume - See low fuel pressure

High fuel pressure - Tight diaphragm, Diaphragm spring too strong,.

Frozen

link, Missing spacer, The 1956 Utility service manual states

"High fuel pressure

may be corrected by adding gaskets between the pump

body and engine block."

Fuel leak at center of fuel pump - Ruptured fuel diaphragm

Fuel in engine oil - Ruptured fuel diaphragm

Low vacuum - Ruptured vacuum diaphragm, Air

leak, Mechanical wear.

Slow wipers - Ruptured vacuum diaphragm, air

leak, Mechanical wear.

Rough idle - Ruptured vacuum diaphragm, air

leak

Oil consumption - Ruptured vacuum diaphragm

Removal

and installation

Caution Gasoline and gasoline vapors are highly flammable. A

fire could

occur if an ignition source is present. Have a dry chemical (Class B)

fire extinguisher nearby.

Remove fuel cap to relieve pressure. Disconnect the fuel and vacuum

lines from the pump. Plug the fuel supply line so gasoline will not

gravity drain from the tank. Remove the 2 bolts that attach the fuel

pump to the engine block. The M38 uses special bolts with and extended

hex section to allow

easier removal and installation of the fuel pump.

Clean the old gaskets from the pump, spacer and the block.

For easier installation of the fuel pump, rotate the engine crankshaft

until the fuel pump camshaft eccentric lobe is on the low point. Look

into the fuel pump opening to determine the low point. Alternately the

engine can be set at top dead center of cylinder number 1 compression

stroke so the lobe is at the low point. Pre-lubricate the fuel pump arm

where it will contact the camshaft. Place the bolts in the fuel pump

holes. Install 1 new gasket over the bolts. Install the spacer over the

bolts. Install the second gasket over the bolts. Insert the fuel pump

arm into the block being sure the arm goes on top of the camshaft

eccentric lobe. Start the bolts in the block threaded holes and evenly

tighten them. Connect the fuel and vacuum lines.

Part numbers

The fuel pump part number is usually

stamped on the edge of the mounting flange. Some high production pumps

have the part number cast into the body beneath the diaphragm flange.

CJ-3A

Pump WO-647911

Spacer WO-647669, approx. 1/8" thick

CJV-35/U

Pump WO-648379, AC-1539556

Spacer WO-647669, approx. 1/8" thick

M38

Pump AC-1539585, WO-800350, ORD-7375380 through engine #74419;

AC-1539917,

WO-807641, ORD-8330132 after engine #74419

Spacer WO-800361, ORD-8329708, approx. 1/2" thick

WO Willys part number

AC Manufacturers part number

ORD Military part number

The following information is copied

from

TM

9-1828A

Fuel Pumps

December 1952

Special

Vacuum Diaphragm Tool

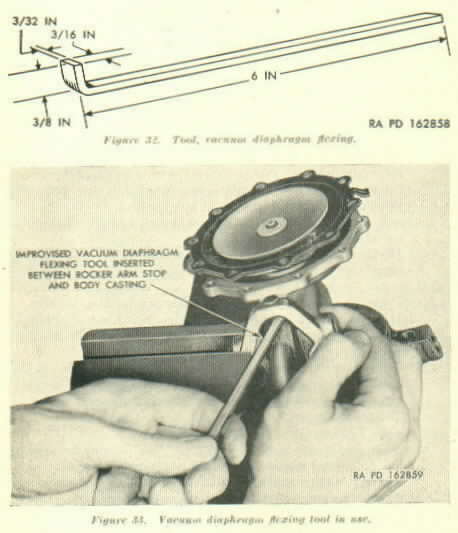

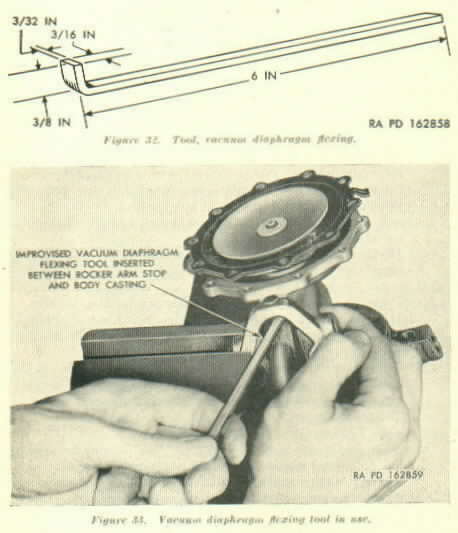

Figure 32 and figure 33, Special Tool

CJ-3A, CJV-35/U pump rebuilding

Section

XXVII. SERIES CF FUEL AND

VACUUM PUMPS

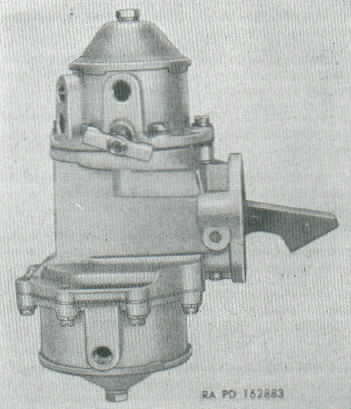

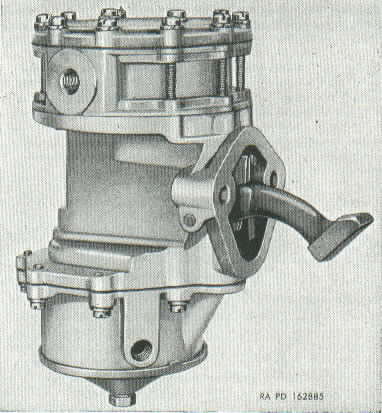

Figure 57. Fuel and vacuum pump,

series CF.

87. Disassembly (fig. 58)

a. Separate

Fuel Cover From Body.

(1) Mark edges of fuel cover and body diaphragm

flanges of series CF fuel and vacuum pump (fig. 57) with a file. Mark

heat shield stud if used. The parts then may be assembled in the same

relative position. Note that the fuel diaphragm flange is symmetrical

and the vacuum diaphragm flange has bulges where the screw holes occur.

(2) Remove cover screws and lock washers. Also remove

heat shield stud, if used. Separate cover from body by jarring cover

loose with a light plastic hammer.

b. Separate Vacuum Cover From Body.

(1) Mark edges of vacuum cover and body diaphragm

flanges. Mark at heat shield stud, if used. The parts may then be

assembled in the same relative position.

(2) Remove only two cover screws front opposite sides

of the cover and substitute for them two No. 10-32 x 1-1/2" fillister

head screws. Turn the two long screws all the way down then remove the

balance of the regular cover screws. Alternately back off the two long

screws, a few turns at a time, until the force of the heavy vacuum

diaphragm spring is no longer effective. Tap the cover with a light

plastic hammer if the flanges stick together. Remove the two long

screws, the cover assembly, diaphragm spring, and spring retainer.

c. Disassemble Body.

(1) File riveted end of rocker arm pin flush with

steel washer. Drive out the rocker arm pin with a drift punch and

hammer. Wiggle rocker arm until links unhook from both diaphragms.

Remove rocker arm spring, rocker arm, and link assembly.

(2) Remove bushing from rocker arm which disengages

two vacuum links, one fuel link, link spacer, and link washers.

(3) Lift vacuum diaphragm out of pump body. Lift fuel

diaphragm out of pump body and remove spring retainer and spring.

d. Disassemble Vacuum Cover.

(1) Remove two screws holding valve and cage

retainer. Lift out valve and cage retainer, two valve and cage

assemblies, and gasket.

(2) Remove bowl screw with gasket. Remove bowl, bowl

gasket and screen.

e. Disassemble Vacuum Cover.

(1) Remove valve and cage retainer screw. Lift out

retainer, two valve and cage assemblies, and two gaskets.

(2) Remove cover plate screw with gasket. Lift off

the cover, cover gasket, screen retainer, and screen.

88. Cleaning and

Inspection (CJV-35/U fuel pumps did not use an oil seal in the body on

the fuel side)

a. Clean All

Parts

(1) Clean all metal parts in dry-cleaning solvent or

volatile mineral spirits. Blow out all passages with compressed air. If

difficulty is experienced in cleaning parts, use

carbon remover solvent.

(2) Check fuel Pump number on edge of mounting flange

and select propel repair kit using table II. All parts in the standard

repair kit must be installed when a

fuel pump has been disassembled

for rebuild.

b. Inspection.. Make the following inspection

of fuel

pump parts which are not included in the repair kit:

(1) Top cover. Discard cover if cracked or broken, or

if the diaphragm flange is warped more than 0.010 inch. If warped less

than 0.010 inch, flatten with disk grinder. Discard

cover if bowl

gasket seat is warped more than 0.010 inch. Discard valve seat

insert-type covers when any part of raised valve seat is worn flush

with shoulder of valve. Stripped or crossed threads

can sometimes be

corrected with a thread chaser, or drilled out and retapped to a larger

size.

(2) Body. Discard body if diaphragm flange is warped

more than 0.010 inch. If warped less than 0.010 inch, refinish with

disk grinder. Discard cover if

threaded holes in diaphragm

flange are

stripped or crossed. Stripped or cross threads can sometimes be

corrected with a thread chaser, or drilled out and

retapped to a larger

size. Discard body if rocker arm stop is broken.

(3) Rocker arm. Discard only if obviously worn or

broken.

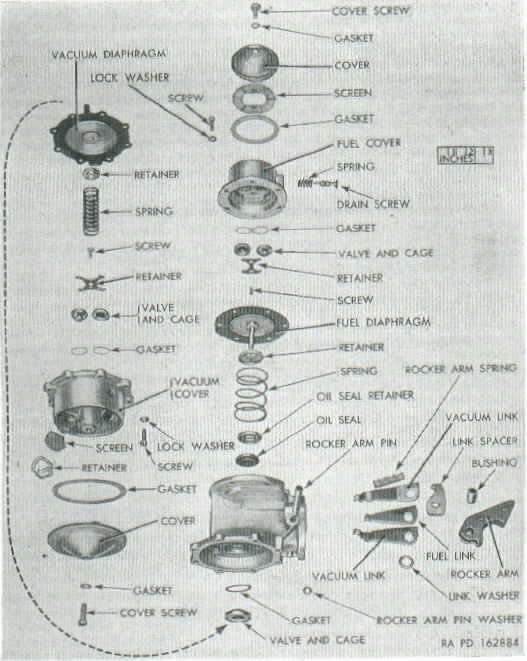

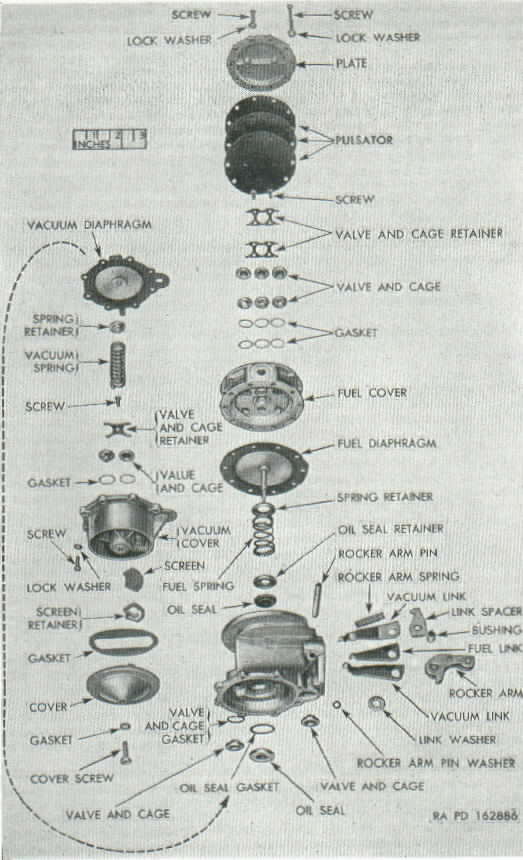

Figure 58 Fuel and vacuum

pump-disassembled view (typical series CF construction)

89. Assembly

a. Assemble Body (fig. 58).

(1) Assemble link spacer over fuel link. Place one

vacuum link out each side of the fuel link. The hook ends of the vacuum

links must come together so they surround the fuel link. All link hooks

should point in the same direction. Place assembly of links and spacer

between lobes of rocker arm with one spacer washer to the outer side of

each vacuum link. Slide rocker arm bushing through holes in rocker arm,

spacer washers, and links.

(2) Stand the pump body on the bench, fuel flange

down. Set rocker arm spring in position with one end over cone cast

into the body. Slide rocker arm and link assembly into body. Outer end

of rocker arm spring slips over projection on link spacer; the open end

of all link hooks must point toward vacuum flange. Align rocker arm

bushing hole with hole in body and retain assembly by driving rocker

arm pin through body and bushing. Place washer over small end of pin

and retain by spreading end of pin.

(3) Soak fuel diaphragm in clean kerosene. Fuel oil

may be used, but do not use shellac or sealing compound. Place spacer

in pull rod well of body casting. Set the diaphragm spring on the

spacer and the spring retainer on top of the spring, dish side down.

Hook diaphragm pull rod to center fuel link.

b. Assemble Fuel Cover.

(1) Place valve and cage gasket or two separate

gaskets in recesses provided. Place valve and cages on top of gaskets.

Inlet valve must have 3-legged spider facing out of cover; the outlet

valve must have 3-legged spider facing into cover. Secure valve and

cage assemblies with retainer and screw.

(2) Install strainer screen, cover gasket, cover,

cover screw gasket, and cover screw in the order named.

c. Assemble Fuel Cover to Body.

(1) Install cover on body, making sure that file

marks on cover and body line up. Push on rocker arm until diaphragm is

flat across body flange. Install cover screws and lock washers loosely

until screws just engage lock washers. Push rocker arm in full stroke

and tighten cover screws securely. Release rocker arm.

(2) Diaphragm must be held in flexed position while

tightening cover screws or pump will deliver too much pressure.

d. Assemble Vacuum Cover.

(1) Place two gaskets and two valve and cage

assemblies in cover. Inlet valve must have 3-legged spider facing out

of cover;

outlet valve must have 3-legged spider facing into cover. Secure valve

and cages with retainer and screw.

(2) Turn cover over, and set screen in recess over valve

hole. Set screen retainer on screen. Place cover gasket, cover, cover

screw gasket, and cover screw in position in the order named. Tighten

cover screw.

e . Assemble Vacuum Cover to

Body.

(1) Soak diaphragm in clean kerosene. Fuel oil may be used,

but do not use shellac or sealing compound.

(2) Lift the pump body above eye level, facing the vacuum diaphragm

flange. The two vacuum links will swing down so that the diaphragm pull

rod can be hooked to both links.

(3) While holding the vacuum diaphragm in position, the body should be

clamped in a vice, vacuum side up. Clamp on either side of the mounting

flange. The vacuum diaphragm must be held level with the body flange

during the following operations. The diaphragm is held level by

inserting a 3/32-inch piece of metal between rocker arm stop and body.

This tool can be made from a piece of steel, 3/16 x

3/32 x 6. Bend one end to form a right angle hook three-eighths of an

inch from bend to end (fig. 32).

(4) Place spring retainer on riveted end of diaphragm

pull rod and the spring on the retainer. Place vacuum cover over spring

and align the file marks.

(5) Insert two No. 10-32 x 1-1/2 screws in opposite

holes in cover flange. Turn these long screws down alternating a few

turns on each. Insert regular screws with lock washers and tighten

until screws just engage lock washers. Replace two lng screws with

regular screws and lock washers.

(6) Remove 3/32-inch tool from rocker arm position.

This allows the heavy vacuum spring to push diaphragm into flexed

position. Tighten all cover screws securely.

f. Test. Fuel and

vacuum pumps cannot be bench tested.

M38

pump rebuilding

Section

XXVIIL SERIES CU AND CY FUEL AND VACUUM PUMPS

Figure 59. Fuel and vacuum pump-series CU and CV

90. Disassembly

(fig. 60)

a. Separate

Fuel Cover From Body.

(1) Mark edges of cover and body of series CU and CY

fuel and vacuum pump (fig. 59) with a file. The parts may then be

assembled in the same relative positions.

(2) Remove only the outer circle of screws (long) and

lock washers. Separate body from cover at diaphragm flange near body.

If cover sticks, it can be jarred loose with a light plastic hammer.

b. Separate Vacuum Cover From Body.

(1) Mark edges of vacuum cover and body diaphragm

flanges. Mark at heat shield stud, if used. The parts may then be

assembled in the same relative position.

(2) Remove only two cover screws from opposite sides

of the cover, and substitute for them two No. 10—32NF x 1½

filster-head screws. Turn the two long screws all the way down; then

remove the balance of the regular cover screws. Alternately back off

the two long screws, a few turns at a time, until the force of the

heavy

vacuum diaphragm spring is no longer effective. Tap the cover with a

light plastic hammer, if the flanges stick together. Remove the two

long screws, the cover assembly, diaphragm spring, and spring retainer.

c. Disassemble the Body.

(1) File riveted end of rocker arm pin flush with

steel washer, or cut off end with 3/8-inch drill. Drive out rocker arm

pin with a drift punch hammer. Wiggle rocker arm until links unhook

from both diaphragms. Remove rocker arm spring, rocker arm, and link

assembly.

(2) Remove bushing from rocker arm to disassemble

rocker arm, two vacuum links, one fuel link, link spacer, and link

washers (there may be one or two link washers).

(3) Lift vacuum diaphragm out of body. Remove fuel

diaphragm by pulling straight out.

(4) The diaphragm pull rod seals must be removed if

they exhibit wear or the sealing surfaces are torn. To disassemble

seals, it is necessary to remove metal displaced by staking operation.

Use a small chisel, round file or small grinding wheel. Pull seals out

of body with hook-shaped tool, being careful not to damage seal seats.

(5) Push the staked-in valve off its seat with a thin

rod or pencil. If the valve sticks to its seat under very light

pressure, if it moves downward and does not rebound, or if the cage is

damaged, the complete valve must be replaced. Remove staking with half

round file and pull valve out with hook-shaped tool.

d. Disassemble Fuel Cover. Remove two cover

center screws and lock washers. Lift off the pulsator cover plate and

three layers of pulsator diaphragm. Remove four screws from each of two

valve and cage retainers. Remove two retainers, six valve and cage

assemblies, and six gaskets.

Figure 60. Fuel and vacuum pump,

disassembled view (typical series CU and CY construction).

91. Cleaning and

Inspection (Please see Modification

of M38 Fuel Pump below for updating your fuel pump)

a. Clean All

Parts

(1) Clean all metal parts in dry-cleaning solvent or

volatile mineral spirits. Blow out all passages with compressed air. If

difficulty is experienced in cleaning parts, use

carbon remover solvent.

(2) Check fuel Pump number on edge of mounting flange

and select propel repair kit using table II. All parts in the standard

repair kit must be installed when a

fuel pump has been disassembled

for rebuild.

b. Inspection.. Make the following inspection

of fuel

pump parts which are not included in the repair kit:

(1) Top cover. Discard cover if cracked or broken, or

if the diaphragm flange is warped more than 0.010 inch. If warped less

than 0.010 inch, flatten with disk grinder. Discard

cover if bowl

gasket seat is warped more than 0.010 inch. Discard valve seat

insert-type covers when any part of raised valve seat is worn flush

with shoulder of valve. Stripped or crossed threads

can sometimes be

corrected with a thread chaser, or drilled out and retapped to a larger

size.

(2) Body. Discard body if diaphragm flange is warped

more than 0.010 inch. If warped less than 0.010 inch, refinish with

disk grinder. Discard cover if

threaded holes in diaphragm

flange are

stripped or crossed. Stripped or cross threads can sometimes be

corrected with a thread chaser, or drilled out and

retapped to a larger

size. Discard body if rocker arm stop is broken.

(3) Rocker arm. Discard only if obviously worn or

broken.

92. Assembly

a. Assemble

Body (fig. 60).

(1) Place fuel section seal in recess of body with

large dished portion of seal down. Press retainer down firmly with flat

end of 7/8-inch diameter round bar. Retain by staking die cast lip in

four places.

(2) Place gasket in recess for vacuum section pull

rod seal and follow with seal, narrow diameter first. Press down firmly

with flat end of 7/8-inch diameter round bar. Retain by staking die

cast lip in four places.

(3) Place neoprene gasket in vacuum section valve

recess next to oil seal and follow with valve and cage, spring and cage

down. Firmly press valve and cage against neoprene gasket and retain by

staking die cast in three places around valve.

(4) Assemble link spacer over fuel link. Place one

vacuum link on each side of fuel link. The hook ends of vacuum links

should come together so they surround the fuel link. All link hooks

should point in the same direction. Place assembly of links and spacer

between lobes of rocker arm with one spacer washer on the outer side of

each vacuum link. Slide rocker arm bushing through holes in rocker arm,

spacer washers, and links.

(5) Place pump body on bench, fuel flange down. Set

rocker arm spring in position with one end over cone cast into body.

Slide rocker arm and link assembly into body. Outer end of rocker arm

spring fits over projection on link spacer. The open end of all link

hooks must point toward vacuum diaphragm flange. Temporarily retain

rocker arm and link assembly with a 4- or 5-inch length of 1/8-inch rod.

(6) Soak diaphragm in clean kerosene. Fuel oil may be

used, but do not use shellac or sealing compound. Turn pump body over

so fuel diaphragm flange is up. Set the diaphragm spring on the

staked-in seal and the retainer on top of the spring. Push diaphragm

pull rod through retainer. spring, and oil seal. Flat of pull rod must

be at right angles to fuel, link. Hook diaphragm pull rod to short,

center, fuel link.

(7) Drive temporary pin out with permanent pin. Place

washer over small end of pin and spread pin end to retain washer.

b. Assemble Fuel Cover. Place six valve and

cage gaskets in cover with six valve and cage assemblies on top of

gaskets. Inlet valve and cages must have 3-legged spider facing into

cover; outlet valve must have 3-legged spider facing out of cover.

Retain each set of three valve and cage assemblies with one retainer

and four screws. Place three layers of pulsator diaphragm on cover, and

follow with pulsator cover plate. Aline two center screw holes, and

insert two screws with lock washers through cover plate, pulsator

diaphragm, and into pump cover. Tighten screws securely.

c. Assemble Fuel Cover to Body.

(1) Install cover on body, making sure that file

marks on cover and body line up. Push on rocker arm until diaphragm is

flat across body flange. Install cover screws and lock washers loosely

until screws just engage lock washers. Push rocker arm in full stroke

and tighten cover screws securely. Release rocker arm.

(2) Diaphragm must be held in flexed position while

tightening cover screws, or pump will deliver too much pressure.

d. Assemble Vacuum Cover.

(1) Place two valve and cage gaskets in recesses

provided and follow with two valve and cage assemblies. Secure valve

and cages with retainer and screw.

(2) Turn cover over and set screen in recess over

inlet valve hole. Set retainer on screen. Place cover gasket, cover,

cover screw gasket, and cover screw in position in the order named.

Tighten cover screw.

e. Assemble Vacuum Cover to Body.

(1) Soak diaphragm in clean kerosene. Fuel oil may be

used, but do not use shellac or sealing compound. Push diaphragm pull

rod through oil seal with flat of pull rod at right angles to double

vacuum links.

(2) Clamp flange of pump in vise with vacuum section

up. Place 12-inch section of pipe over rocker arm and rise vacuum links

by moving rocker arm. Tilt diaphragm pull rod away from links, and as

links are raised, bring pull rod back to vertical. Repeat until pull

rod is securely hooked to both links.

(3) The vacuum flange must be held level with the

body flange during the following operations. The diaphragm is held

level by inserting a 3/32-inch piece of metal between rocker arm stop

and body. This tool (figs. 32 and 33) can be made from a piece of

steel, 3/16 x 3/32 x 6. Bend one end to form a right angle hook

three-eighths of an inch from bend to end (fig. 32).

(4) Lift diaphragm cloth and position valve and cage

in recess close to mounting flange. No gasket is required because the

diaphragm seals this valve cage.

(5) Place spring retainer on riveted end of diaphragm

pull rod and place the diaphragm spring on the retainer. Place vacuum

cover over spring and align file marks.

(6) Insert two 10-32NF x 1½ screws in opposite

holes in cover flange. Turn these long screws down, alternating a few

turns on each screw. Insert regular screws and lock washers and tighten

until screws just engage lock washers. Replace two long screws with

regular screws and lock washers.

(7) Remove 3/32-inch tool from rocker arm position.

This allows the heavy vacuum spring to push diaphragm to flexing stop

in body. Tighten all cover screws securely.

f. Test. Fuel and vacuum pumps cannot be

bench-tested.

Modification

of M38 Fuel Pump

From TM 9-8012, Jan 1956

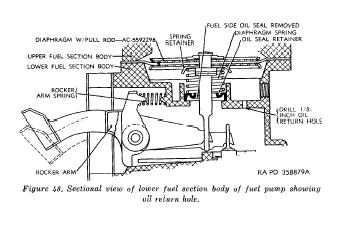

b. Modification of Fuel Pump (fig. 48). To minimize premature failures

of fuel pumps caused by excessive pressures within the fuel pump and

the trapped oil in the lower section of the upper body, modify the pump

as described in (1) through (8) below.

(1) Remove machine screw and lockwashers which secure the flanges of

the

upper and lower section bodies.

Note. Scribe marks on outer edge of flanges for alignment during

assembly.

(2) Remove upper fuel section body, diaphragm with pull rod, spring

retainer, and diaphragm spring.

(3) Using a hook-shaped tool, remove oil seal retainer and oil seal.

Exercise care during this operation to prevent damage to oil seal

retainer.

Note. If oil seal retainer is staked in place, remove the staking with

a small chisel, round file, or grinding wheel before pulling the

retainer and oil seal from the pump.

Discard the oil seal but retain the oil seal retainer if fuel pump

repair kit G740-73’75384 is used. Discard the oil seal and retainer if

fuel pump repair kit G758-8329981 is used.

(4) Drill a l/8-inch hole in deck of body (fig. 48) to act as an oil

return and pressure relief hole. Metal clips resulting from the

drilling should be blown from the fuel pump with compressed air.

(5) Install new oil seal and original retainer when using fuel pump

repair kit G740-7375384; if fuel pump repair kit G758-8329981 is used,

install oil seal retainer G758-8329706.

(6) Install diaphragm spring and spring retainer.

(7) Install new diaphragm with pull rod after soaking it in clean

kerosene. While holding the diaphragm flange in the upward position,

insert the pull rod through the

spring retainer, spring, and oil seal retainer in the lower fuel

section body. The flat of the pull rod must be at right angles to the

fuel link. Hook the pull rod to the

short (outer) fuel link.

(8) Aline the upper fuel section body on the lower fuel section body in

accordance with marks scribed in (1) above. Push on rocker arm until

diaphragm is flat across body flange. Install original screws and

lockwashers until screws just engage lockwashers. Push rocker arm in a

full stroke and tighten screws securely. Note. Diaphragm must be in

fixed (down) position while tightening cover screws, or pump will

deliver too much pressure.