M38 Underwater Ventilating System

This information is what I have found to be

accurate. I make mistakes; use this information at your own

risk. If

you notice any errors, or have any other comments please contact

me. Click here for contact

information.

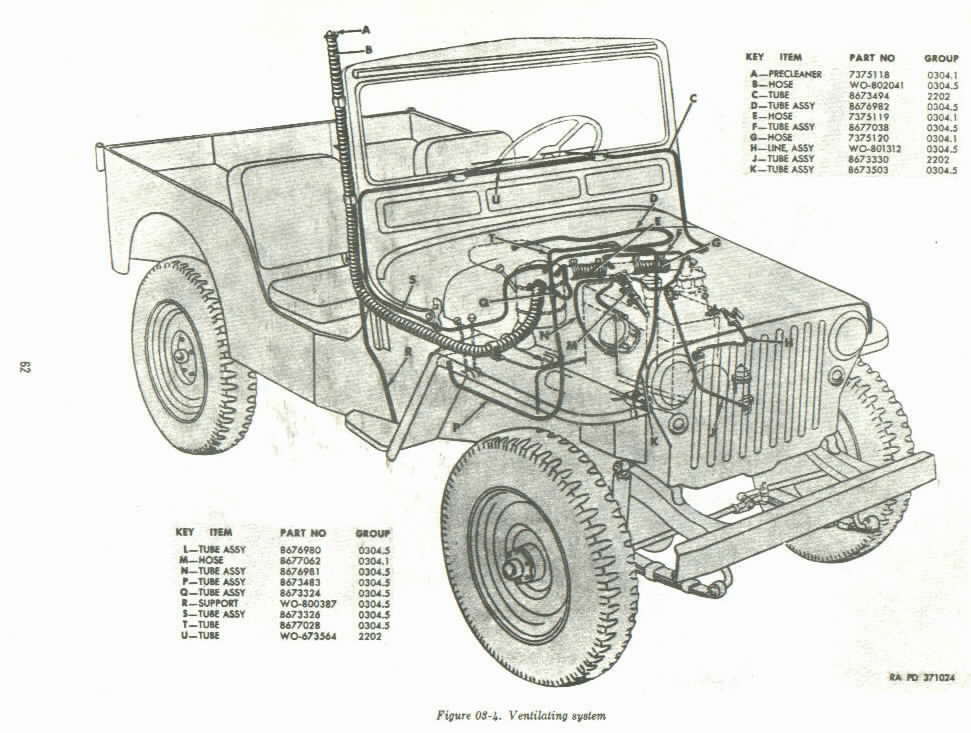

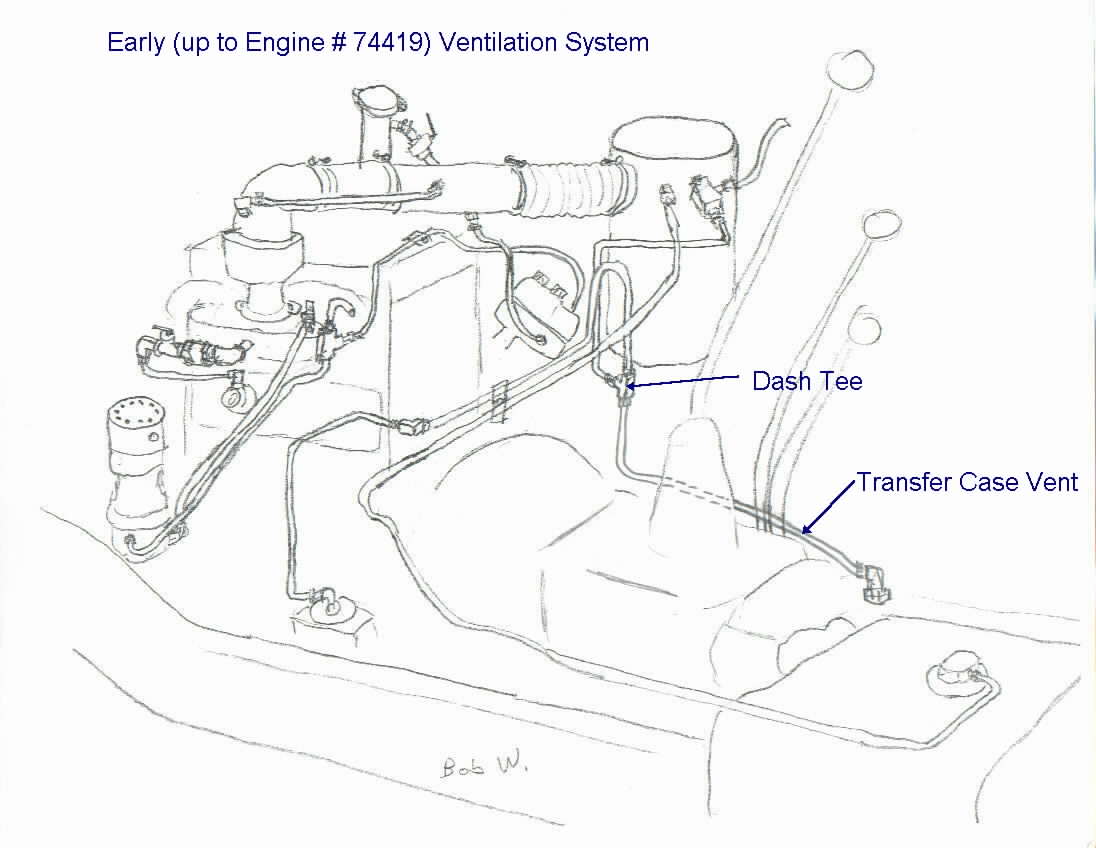

The M38s came from the factory with the underwater ventilating system installed. During the three model years production of the M38, a few changes were made to the underwater ventilating system.

Up to Engine serial number 74419 the bellhousing was not sealed. The transmission and transfer cases were vented to the air filter. I will refer to this as the Early system.

M38s after Engine serial number 74419 had a sealed bellhousing. The bellhousing, transmission, and transfer case were pressurized while fording. I will refer to this as the Late system. TM 9-8012 (Jan 1956) indicates that at vehicle serial number 53262 the change to late venting systems was made. This serial number would have a Date Of Delivery of about February 1952.

The combination of the underwater ventilating system and the installation of 801080 Deep Water Fording Kit enabled the M38 to drive through water up to 74" deep. The Deep Water Fording kit contained an extended intake hose, extended exhaust pipe and the necessary brackets to install them.

Due to repairs and modifications made by owners, it is difficult to find intact examples of the original underwater ventilating system. The M38 service and parts manuals seem to have a few errors and omissions. I attempted to locate each part and part number using service manuals, parts manuals and an actual vehicle, MC61956. Since the M38 and M38A1 are very similar, the M38A1 manuals are helpful. This information was obtained from ORD 9 SNL-G740, ORD 9 SNL-G758, and TM9-1804A. Thanks also to members of the Yahoo M38-M38A1-M606 group for all their help.

This page contains a description of the operation of the underwater ventilating system. Page 2 contains parts information for the underwater ventilating system with photos.

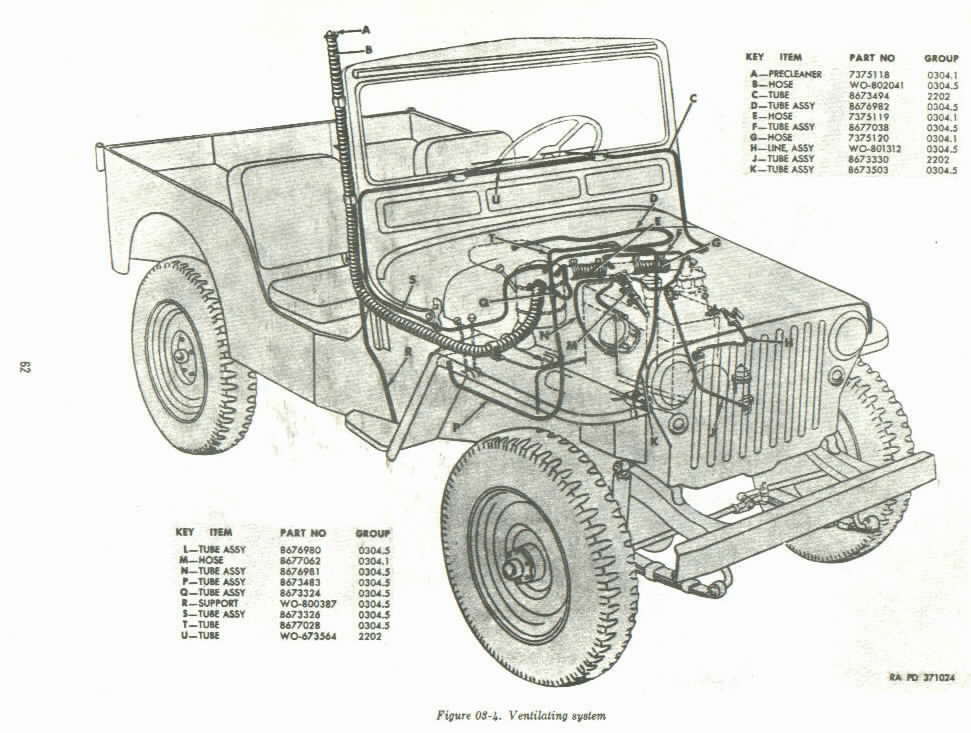

Late style Underwater Ventilation System

The underwater ventilating system can be broken down into seven separate systems. I have numbered the systems to help identify them. System 1 and 2 are normally independent. On the late style only, Systems 1 and 2 are connected during fording operations. Systems 4 and 5 share the same vacuum supply (the wiper Tee).

1. Engine crankcase venting

2. Transmission and transfer case (also the bellhousing on late style systems)

3. Carburetor venting

4. Distributor venting

5. Windshield wiper venting

6. Fuel tank venting

7. Master cylinder venting

1. Engine crankcase venting

Ventilation of internal combustion engines is necessary to prevent harmful condensation, to relieve internal pressures set up by the action of rapidly moving hot parts, and to rid the crankcase section of volatile vapors. When the M38 was built, engines were usually vented directly to the atmosphere through suitable openings or vents. The M38 engine is of waterproof construction. Because it is waterproof, or watertight, it is also airtight. Therefore, the method used to ventilate the engine is different than that of most engines of the time period. It uses the system that is on most modern automobiles, the PCV (positive crankcase ventilation) system. A PCV system is a closed system within the normal engine intake air and exhaust systems. During normal operation with the engine running, the vacuum created in the engine intake manifold draws fresh air into the ventilating system through the upper crankcase vent control valve on the air intake pipe assembly. The flow of air enters the oil filler pipe. The air then passes downward into the crankcase.

The contaminated crankcase air leaves the cylinder block at the side valve cover through the series of parts that include the lower crankcase vent control valve and the metering valve (PCV valve). The air is then sucked into the engine intake manifold. From the intake manifold the air is drawn into the cylinders, burned, and then exhausted into the engine exhaust system.

During normal operation the two vent control valves are open and play no part in the ventilating system. The metering valve (PCV valve) however, operates to automatically control the amount of vacuum developed within the engine regardless of the engine speed. Prior to entering deep water, the vehicle operator installs the 1/4 inch pipe plug in the drain opening in the bellhousing (late system) and closes the two vent control valves by pulling the control cable on the dash. Closing the vent valves renders the entire engine ventilating system inoperative. This does not include the vent system of the carburetor, wipers, master cylinder, fuel tank and the distributor, which are vented independently of the engine. When the vent control valves are closed with engine running, the unrelieved pressure within the engine builds up to approximately 2-psi. Internal pressure rarely goes higher than 2-psi because, at higher pressure, leakage occurs through the crankshaft front and rear oil seals. This internal pressure offsets the external pressure of the water surrounding the engine and effectively prevents the entry of water into the engine past imperfectly sealed joints or through the front or rear oil seals.

2. Bellhousing, transmission and transfer case venting, Early and Late style systems

These three components normally need to be vented to the atmosphere to eliminate internal pressure or vacuum from forming as they heat and cool with use.

Late system. On the late M38, the bellhousing, transmission and transfer case are all connected. The transmission is connected to the transfer case by internal passageways. The transfer case has a tube from the normal vent location to a Tee fitting on the driver's side of the bellhousing. This Tee also has a line that continues to a check valve on the center section of the fuel pump. During normal operation, the bellhousing is connected to the atmosphere through the threaded drain hole in the bottom. This allows the bell housing, transmission and transfer case to vent to the atmosphere. For fording operations the operator installs a plug in the bellhousing drain hole to seal it. During fording the engine crankcase is slightly pressurized. This pressure passes through the center of the fuel pump, unseats the special fitting check ball, and pressurizes the bell housing, transmission and transfer case. The purpose in raising the internal pressure of these units is to give them the same protection against the entry of water that is given the engine.

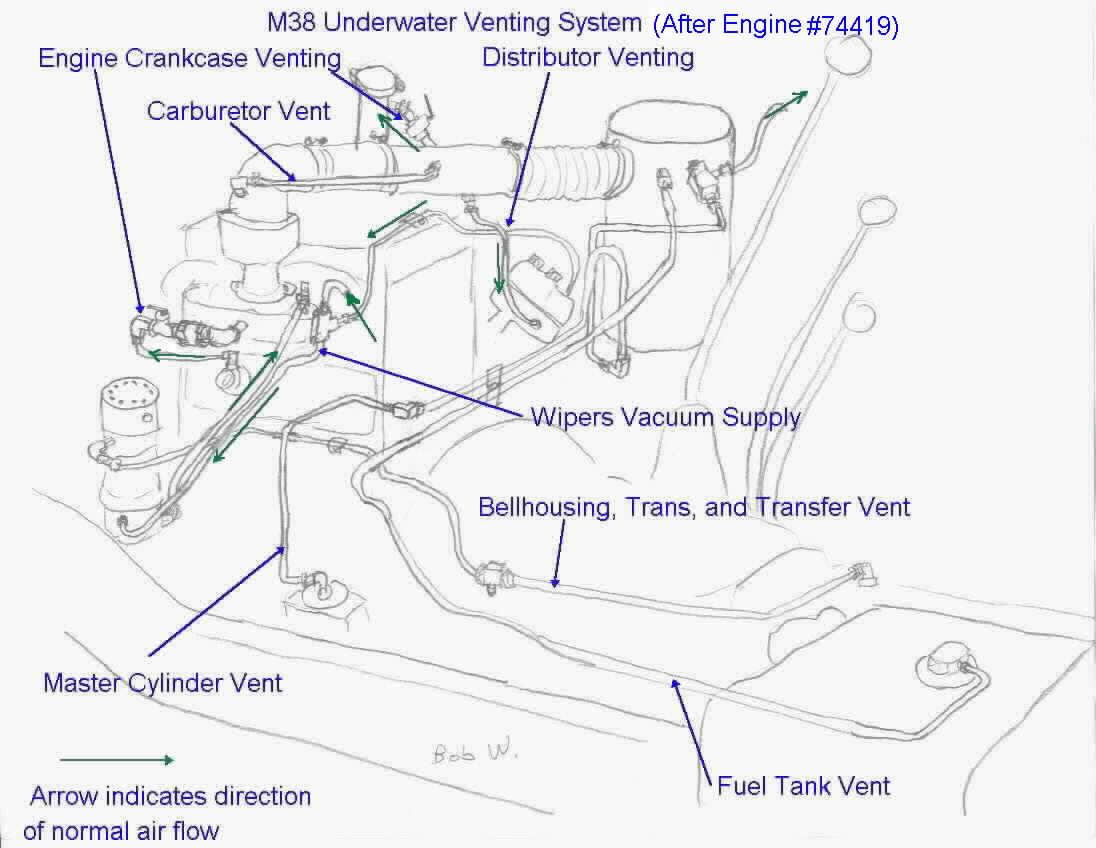

Early system. Early M38s did not have a sealed bellhousing. There was no bellhousing Tee and there were no fuel pump center fittings. The transfer case vent line was connected to the air filter via the dash tee fitting. The bellhousing, transmission and transfer cases were not pressurized during fording operations on the early vehicles.

Early style Underwater Ventilation System

3. Carburetor venting

The upper section of the carburetor must be open to atmospheric pressure to maintain a balanced condition in the carburetor. Therefore, the carburetor is vented by means of the vent line that is connects the top of the carburetor to the air intake pipe.

4. Distributor

The distributor needs to have a supply of fresh air to avoid build up of water vapors inside the cap. The rear inside of the distributor is connected to the air crossover pipe by a metal line. This line supplies clean air to the distributor.

The outside front of the distributor is

connected

by a metal line to a special fitting in the vacuum wiper supply

Tee.

The special fitting has a .040" restriction to limit the amount

of

vacuum in the distributor to a predetermined value regardless of

the

engine speed. It is also interesting to note that the two

distributor

vent lines are copper, while most of the venting system utilizes

copper

plated steel lines.

5. Windshield wiper venting

The vacuum supply to operate the windshield wipers comes from the intake manifold. To insure a constant vacuum regardless of engine speed the vacuum booster section of the fuel pump is connected in series between the intake manifold and the wiper supply Tee fitting.

Since the vehicle can be submerged, the wipers need to have a fresh air source to avoid ingestion of water. This fresh air comes from the Tee fitting on the rear of the air filter housing.

6. Fuel tank vent

The fuel tank is vented by a copper line that runs from the top of the fuel tank to the rear of the air filter housing. The fuel tank is equipped with a pressure relief valve that will permit pressure to build up in the tank to a maximum of 4 psi. The cap is a solid-type pressure cap designed for use only with this vehicle and should not be interchanged with the vented-type pressure cap, used with 3/4-ton trucks, which open and release excess pressure. The solid-type cap used with truck M38 has a cup about 3-1/2 inches in diameter, inside of the shell, with a rivet in the center of the cup and a safety chain riveted about 1 inch off center. The cap used on the truck M38 is marked with embossed letters or decalcomania with the word pressurized and instructions to open slowly.

7. Master cylinder vent

The brake master cylinder is vented through a line that extends up between the foot pedals to the left dash elbow, mounted on the firewall. Another line crosses the firewall to the right side dash elbow. From there, a line continues to the air cleaner. On the early style venting system the "Dash Tee" was used in place of the right side elbow. The additional connection point is where the transfer case vent line was connected.

Continue to Page 2 for parts information for the underwater ventilating system.

9/7/2024