Home | Site Map | Contact Information

The Evolution of Deep Water Fording and the Jeep

|

Many

times during W.W.II jeeps were

involved in beach landings. The jeep in the photo to the left seems to

be having

trouble getting from the landing

craft to the beach at Cape

Gloucester, New Britain. The Marines are helping it

along by pushing. Vehicles stuck in the water could present a serious

problem during a combat landing. Click on the image for a

larger view. |

|

Perhaps the military leaders thought the amphibious jeep would be the solution. The "Rifkind Report" (1) cites much correspondence between the military and its manufacturer in 1942. The desire was to get quantities of the GPA "Seep" produced quickly. Mechanically the GPA was very much like the standard jeep. Instead of a body on frame, it had a hull and was equipped with a propeller and rudder. We know now that the GPA did not live up to it's expectations. It was clumsy on land and sea. The solution to the beach landing problem was deep water fording kits. This allowed the regular jeep to quickly make its way from a landing craft, through the water and onto the beach. |

| MB/GPW (G503) The recommended maximum fording depth of an unmodified jeep was 21 inches. That is about the height of the fuel pump and transfer case vents. Any deeper and things would start to fill up with water. Even at this relatively shallow depth the Technical Manual (2) advised that the generator brace should be "pulled up to release tension on the fan belt and stop the fan from throwing water over the engine". That would be important in order to keep water off the ignition system. During a combat landing the 21" maximum fording depth was not adequate. |

|

Lloyd

White photo

|

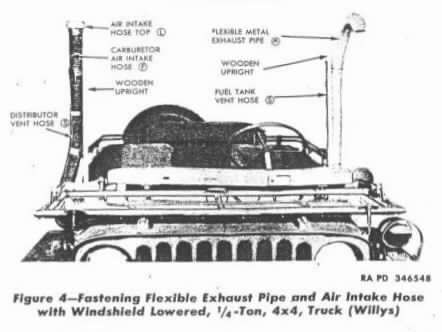

Experiments, ideas and solutions Willys and the military experimented with various ideas to make the jeep more waterproof. Troops in the field undoubtedly modified their jeeps as they deemed necessary to get the job done. The distributor and ignition system would have to be sealed. That could be done easily, just plug the vent holes in the distributor and seal the cap and wires with glue and grease. The Carter WO carburetor must have provided the biggest challenge to waterproof. The accelerator pump linkage provides an easy path for water to enter the float bowl, but difficult to waterproof since it needs to be free to move with the accelerator. An intake snorkel would need to be added since the air filter draws air from low under the hood. The exhaust system was probably ok unless the engine stalled while fording. If that happened water would flow back into the engine preventing a restart. A War Department Film Bulletin, Issue No. 96, explains how to waterproof the jeep for an invasion using this technique. Pictures of early fording ideas can be found among old photos of W.W.II. The upper photo recently sold on eBay and was dated December 4, 1942. The lower photo from mid 1944 shows Marine Corps radio equipped jeeps on Guam. The jeeps have holes cut in the hood above the carburetors to allow an intake snorkel to be attached directly over the carburetor. The far jeep has its snorkel in place. It also has the muffler mounted on the frame in front of the grille. Radio jeeps needed to be first on the beach so it was important for them to have fording equipment. |

WV-6

kit components

Intake

and exhaust snorkels installed

|

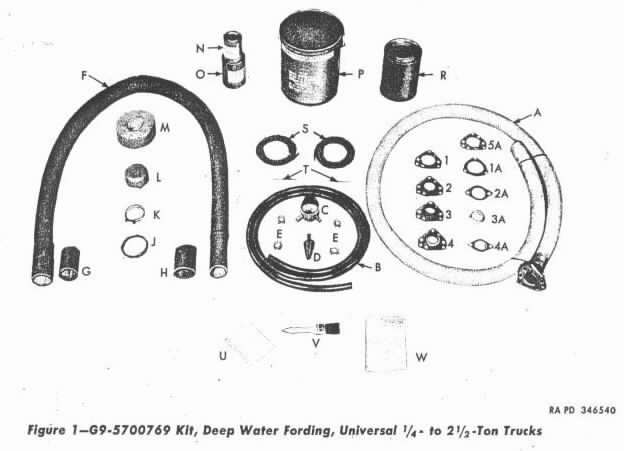

Deep Water

Fording Kit WV-6 TM-9-2853 (9) describes how to prepare tactical vehicles for deep water fording in a combat landing using the WV-6 kit. This waterproofing was designed to provide satisfactory operation for 8 minutes at a depth up to 54". That's about up to the top of the steering wheel. Deep Water Fording Kit WV-6, Stock No. G9-5700769, was a universal kit for Trucks 1/4 to 2-1/2 tons. It consisted of varnish, insulation compound, asbestos grease, glyptal paint, non-hygroscopic adhesive tape, high temperature cement, cloth, assorted hoses, gaskets and adapters. Waterproof vents were to be installed on the distributor and fuel cap, then intake and exhaust snorkels were installed. The instructions also describe how to seal every component on the vehicle with the various compounds included in the kit. The carburetor was to be sealed by covering it with the supplied cloth and then applying asbestos grease over everything. A 1/2" thick layer of asbestos grease was to be applied to the distributor, spark plugs and ignition coil. Complete waterproofing would take many hours to complete. The instructions then detail the procedure for driving the vehicle underwater. First run the engine until it is warm, not hot. Deflate the tires to 50% of recommended pressure. Pull the choke out 1/4 of the way to compensate for the cooling effect of the water. Put in 4 wheel drive low range 1st gear and do not shift. As the front wheels enter the water increase engine speed to 3/4 throttle. And finally do not remove right foot from accelerator pedal until out of the water. With this, and every fording system to follow, the recommended post swim maintenance list was quite extensive. |

|

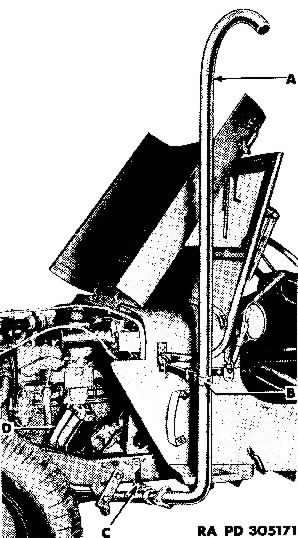

Deep Water Exhaust Kit part number

A-7726 (10) manufactured by

Willys Overland. Like the

WV-6 kit, the vehicle's muffler was not used while the fording pipe was

connected.

It is interesting that this kit is only for the exhaust system and

doesn't provide any waterproofing for the remainder of the vehicle. |

|

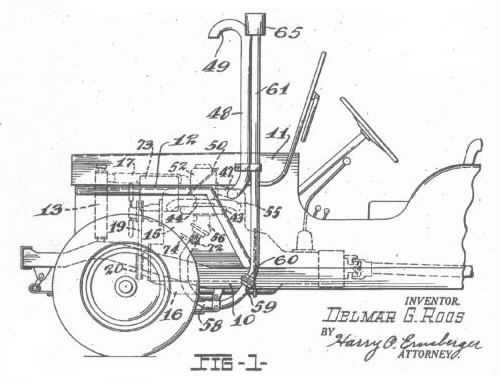

Patent #2,429,732 A patent request

was filed on January 4, 1945 by Delmar G. Roos for a "System and

Apparatus for Operation Submerged Internal Combustion Engines"

This System was a complicated arrangement that used regulated exhaust

gasses to provide positive pressure in the engine crankcase while

submerged. The patent drawings show the system installed on a

military jeep. Instead of a waterproof carburetor and distributor,

special sealed housings enclosed those components. The driver was

responsible for keeping the three under hood valves in the correct

position for regular or underwater operation. Additionally the

exhaust condenser chamber had to be drained regularly. |

| MZ-2

The MZ-2 was a limited production jeep designed to carry communication

radios. It

had an ignition

and generating system that was water resistant, but was not fully water

proof. It also used the deep mud exhaust, which was the beginning of an

exhaust system that could use the later deep water fording accessories.

Although this jeep was not completely waterproof, it was the beginning

of

factory installed fording equipment. RF noise suppression and

waterproofing seemed to go hand in hand. |

|

|

MX-735 Waterproofing Kit This kit was designed for the Navy and supplied by Willys-Overland for use on Marine Corps CVD radio jeeps.

The kit also fit on the G503, W.W.II jeeps. It consisted of numerous parts to

be installed on the jeep to make it waterproof. Everything from a new

dipstick to a new speedometer were included in the kit. The distributor

was

replaced

with a waterproof metal clad unit. The spark plugs and wires

changed to waterproof

"aircraft" type. A waterproof

Carter YS carburetor

replaced the

standard WO carburetor. Fittings and vent lines were included to allow

an atmospheric vent system to be attached to the transfer case, master

cylinder and fuel tank. Two valves activated by a control on the dash

allowed the engine crankcase

to be naturally pressurized slightly while fording. The electrical

system was

upgraded with

waterproof generator, regulator, starter, switches, horn and wiring.

This must have taken a considerable amount of time to install, but when

completed,

the jeep was always ready to ford, unlike the earlier WV-6

kit. |

|

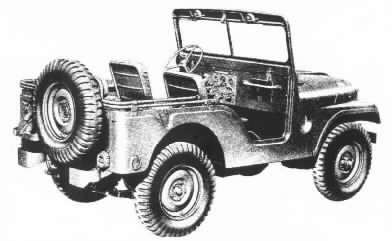

CJV-35/U

In 1950 the first production Jeep with factory-included deep water fording capabilities was manufactured. This Jeep was the CJV-35/U. "This vehicle is designed for short period operation under water to a depth of approximately one foot over the engine hood" according to the Care and Operation Manual (3). The vehicle was based on a civilian CJ-3A which was modified for the military. The fording system was very much like the MX-735 kit. This Jeep was designed to ford without any modification-just pull the handle on the dash and it was ready to go. The special engine ventilation system provided a slight internal pressure in the engine crankcase to help keep water out. The master cylinder, fuel tank, transmission and transfer case were vented to the air filter and the 6 volt electrical system utilized several special water resistant and water proof components, but was not fully waterproofed. The distributor was a special waterproof unit manufactured by Scintilla Magneto Division of Bendix Aviation Corporation. The carburetor was a waterproof Carter YS series. The vehicle also had a unique clutch hole cover that was designed to prevent free flow of water through the clutch housing when the vehicle was submerged. "This cover is not designed to make the housing watertight but as a baffle to prevent free flow of water through the housing. It is essential that the cover be installed as shown, for underwater operation, as otherwise the clutch assembly acts as a water pump impeller and considerable engine power is dissipated" states the Technical Services Manual. (4) Only 1000 CJV-35/Us were built in the first half of 1950 for use by the USMC. Click here for more information about the CJV-35/U underwater ventilation system. |

|

M-38

(G740) & M-38A1 (G758) |

|

M-38 In September 1950 the M-38 entered production. It continued to utilize the new fully waterproof ignition and 24 volt "M series" electrical systems. The fording depth was 30" without the optional Deep Water Fording Kit, part number 801080. This kit contained an extended intake hose, extended exhaust pipe and the necessary brackets to install them. The combination of the factory included underwater ventilating system and the installation of the Deep Water Fording Kit enabled the M38 to drive through water up to 74" deep. That is over the top of the windshield! The early production underwater ventilation system was an updated version of the system used on the CJV-35/U. An important improvement was to isolate the fuel tank vent from the master cylinder vent. With the prior venting system it was possible for fuel to make its way into the brake system through the vent lines. This could cause damage to the brake system and lead to eventual brake failure. |

| Late M-38 At vehicle

serial number 53262 (7) the M-38 underwater ventilation system was

improved. Serial number surveys of existing vehicles indicate the date

of delivery

for this change could have been about February 1952. See the Willys Military Jeeps

web-site for more information. In this system the bellhousing

was sealed and

connected by additional lines to the transfer case and engine

crankcase. These new improvements allowed positive pressure from

the engine crankcase to additionally pressurize the bellhousing,

transfer case and transmission. The late system also required the

operator to take one extra step before fording. A plug needed to

be installed in the bottom of the bellhousing before fording to

complete the seal. Click here

to link to the M-38 Underwater

Ventilation System

article for more information about this system. |

|

|

Early M-38A1 and M-170 The M-38A1 standard fording depth was 37-1/2". An optional kit was necessary for deep water fording, like the M-38. The early M-38A1 used the same underwater ventilation system as the late M-38. The routing of the lines was slightly different since a new engine went into production with the M-38A1. The new F head engine provided 20% more horsepower than the previous L head engine. It utilized the same type of carburetor, ignition system and electrical systems as the M-38. |

| M-38A1 Very early in the M-38A1s production the

trend

of

building "ready to ford" Jeeps was reversed. It had been approximately

7

years

since an

entire fleet of Jeeps needed

to have fording capability. Since

most Jeeps never

went swimming, perhaps it was cost savings that prompted the elimination of some factory installed

fording system parts. After

serial number 23359 (6) the fuel

tank vent

line, transfer case, transmission and bellhousing vent lines and the

engine vent valves were eliminated. Then the master cylinder vent was

eliminated at serial number 29295.(6) These changes would have occurred about October/November 1952 according to a

serial

number list of

existing vehicles on The

M-38A1

Restoration Site. The

eliminated components could be retrofitted to the vehicle if its

intended use required fording capability. |