Home | Site

Map | Contact Information

Carter

WO Carburetor Metering Rod Adjustment

The height of the metering rod in a Carter WO carburetor can be set by

using a special tool designed for this purpose. The use of three

different

setting tools is compared here. Obtaining the special Carter

Metering Rod Gauge is not always possible so this page also explains

some alternatives. For complete Carter WO carburetor reconditioning

instructions visit the Mighty Mo website here.....

http://mightymo.org/Proj_Carter_WO_Rebuild.html

Setting

the metering rod in a Carter WO carb.

By Carl Darnell

I tried to do the best at measuring as I could because I know the info

will out there for everyone to see. I think a lot of people that

overhaul their carbs just put the new metering rod and jet in and

expect it to be the right setting. However, my finding the rods are not

the same length and while I didn't measure the depth of the taper in my

jets I suspect they vary a few thousandths as well.

Comparing the metering rod setting

tools

In an effort to find the easiest or best way to set the metering rod I

did a comparison of the Carter tool, the Snap-On tool and the Home made

tool. I have three metering rods and jets to use to compare with a

borrowed Carter tool and a Snap-On tool and my own Home made tool.

The jet has a tapered opening of 116 deg with a hole of .070”

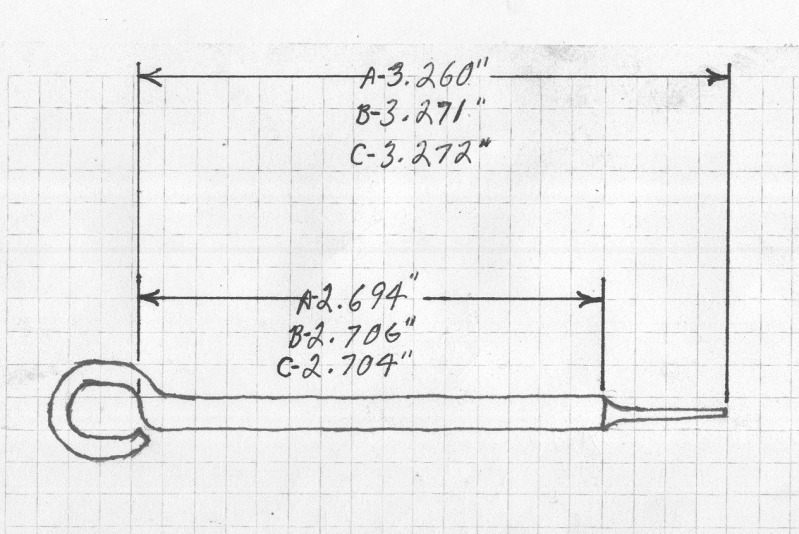

+.000 -.0002” as measured in the three jets I have. The metering

rods vary in length from the start of the tapered area to the spot the

pin rests on. The OAL length of the rod from the spot the pin rests on

to the tip also varies as shown below in the drawing.

Metering Rod Dimensions

I also used one

of the cleaner jets to measure the OAL of the bottom on the jet to the

shoulder of the tool for a reference and they are as follows:

Carter tool, shoulder to bottom of jet = 2.947”.

Snap-On tool, shoulder to bottom of jet = 2.946”.

Home made tool, shoulder to bottom of jet = 2.945”.

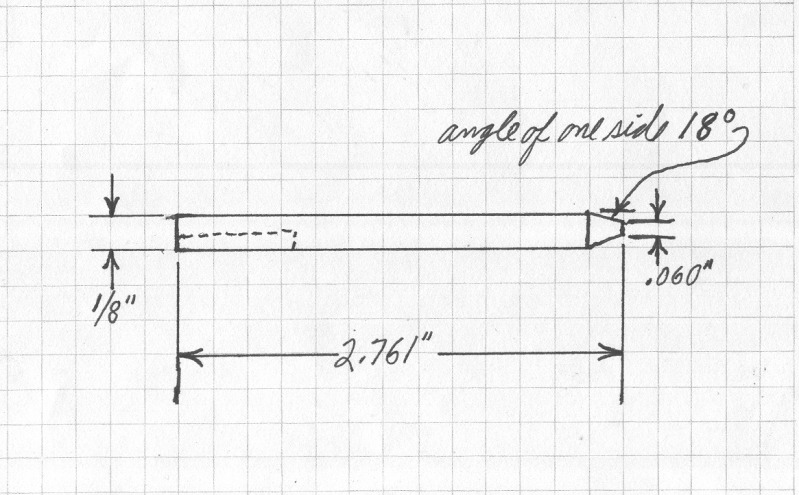

Below is a photo of the Carter, Snap-On and Home made tool. The tip

angles and lengths of the tools vary as follow.

The Carter tool has a tip angle of 58 deg with an OAL from the shoulder

to tip of 2.782”. The length of the shoulder to contact area in

jet is 2.720” and may be 2.718” as it’s hard to read

a line scratched in dykem clearly on the surface of an extremely rough

finish.

The Snap-On tool has a tip angle of 42 deg with an OAL of 2.804”

from shoulder to tip. The length of the shoulder to contact area of the

jet is 2.718” and was clear to read because the tip was very

smooth.

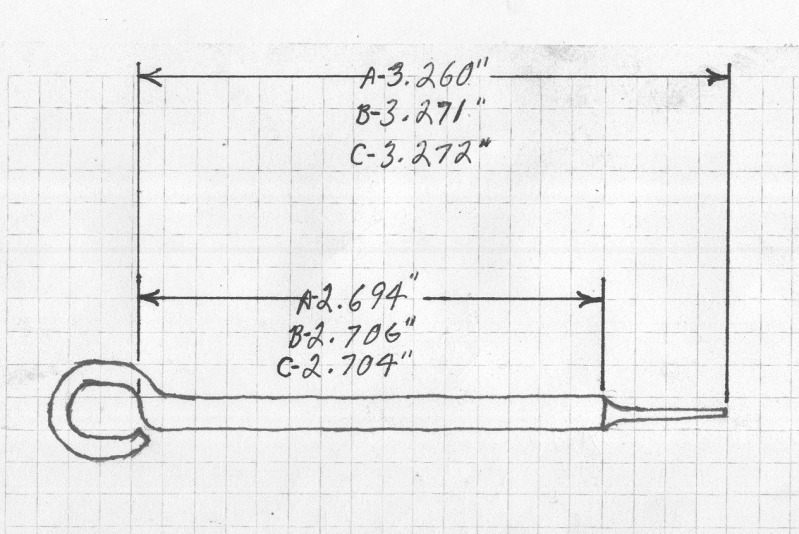

The Home made tool I made has a tip angle of 36 deg with an OAL of

2.761”. The length of the top end to the contact area of the jet

is 2.719” The tip on my tool is as smooth as the Snap-On tool.

I measured them several times to be sure I was as correct as possible.

I used dial calipers along with a 10 power glass and a jig to hold the

rods as I made the measurements. I also used a Peak brand 10 power

comparator to do the small measurements. I was as careful as I could

but some readings could be off a thousandth or two.

Metering Rod Setting Tools

Here is a drawing of the Home made tool from the Internet that I made

to save you from looking it up. I paid close attention to getting is

exact as possible and it must have worked as will be shown in the

following tests of all three tools. You will note a dotted line on the

drawing that indicates where I ground away half of the diameter for

about ½” down the shaft to clear the backing washer on the

pin where the metering rod sits. Since the Carter and Snap-On tools are

flat stamped metal and the rod is 1/8” diameter there will be

some interference so don’t force it or you will get a false

reading.

Home Made Metering Rod Setting

Tool

Now for comparing them on the carb on my Jeep. When I checked my

current setting it had .005” free travel of the rod with the

throttle screw backed off all the way to close the throttle plate. That

means with a dial indicator on the top of the rod I could move the rod

up .005” while holding the throttle closed.

When I put the Carter tool in place of the metering rod I had to loosen

the nut and reset the pin and tighten the nut. When I checked the free

travel using the metering rod I now have .040” free travel using

the dial indicator as noted above.

Then I removed the metering rod and installed the Snap-On tool and the

setting was the same as with the Carter tool. As I moved the tool I

could just feel it touching the bottom of the pin.

Then I removed the Snap-On tool and installed the Home made tool and

the result was the same. Moving the Home made tool under the pin I

could just fell the tool as it rubbed the bottom of the pin.

All three tools gave the same setting of the metering rod pin. I

wasn’t expecting that they would be that close but they are.

Because of the differences in the dimensions of the metering rods and

possibly the jet don't expect replacing the metering rod and jet in an

overhaul without resetting the pin to end up with the correct setting.

It could be way off.

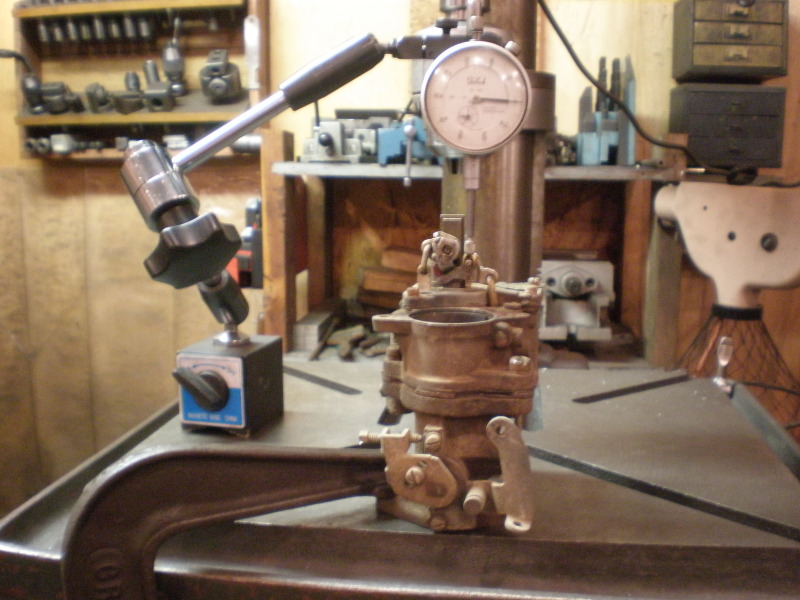

Alternate dial indicator method of

setting the metering rod

Knowing what I found a careful person with a dial indicator and

magnetic base could set the metering rod without a tool by setting the

free travel of the rod to the .040" I found mine to have after using

the correct tools. Clamping the carb to a flat metal bench and using

the mag base indicator next to it would do a good job IF YOUR CAREFUL

and use a very flat work bench or drill press table.

In the photo below I have the dial indicator set up on the exhaust

manifold

and against the head in a spot where it is solid and doesn't move. You

have to back the throttle screw off 6 full turns to be sure the

throttle plate is closed. The plunger is set on the metering rod with

the plunger as straight in line with the metering rod as I can get it.

Then I set the dial on "0" to start to set the rod. Then you loosen the

pin nut just so it will slip, push the pin down gently on the metering

rod loop bottom and then with tweezers lift the rod until the dial

indicator shows .040" and lock the pin nut. Check the travel by moving

the metering rod up and down between the jet and the pin and it should

still be .040". If not reset it until it is. It is important that the

plunger tip touch only the metering rod and not the washer on the pin.

On Vehicle Dial Indicator Metering Rod

Adjustment

Setting the metering rod on the bench is a little easier but you still

use the same method as above while the carb is clamped to a drill press

table. See photo below. The tip I used in the dial indicator has a flat

face but didn't screw all the way in the plunger but it is bottomed out

in the threads. You can use the rounded tip that comes with the dial

indicator but you have to be very careful to get it centered on the

metering rod and not touching the pin washer to get a good reading.

Most people would find it easier using the Carter tool or a home made

tool.

On the Bench Dial Indicator Setting

The CJ-3A Story | CJ-3A

Photos | CJ-3A Specs and Tech Tips | CJ-3A Literature | Siblings of the CJ-3A | Accessories | Links

www.CJ3A.info © 2012