Home | Site

Map | Contact Information

A

Brief History of 1940s

Waterproof Navy and Marine Corps Radio Jeeps.

by Fred Coldwell

|

Willys developed the first WW II

era

purpose-built radio jeep in fall 1942 at the request of the Navy,

which was looking for a small light weight vehicle to carry 12 volt

mid-range command radio sets during the Pacific island-hopping

campaign. The WC 3/4 ton Dodge 12 volt radio command car and

carryall were too large and heavy for swift water borne invasions, so

Willys took the 12 volt 55 ampere Auto-Lite generator that powered

the Dodge electrical system and installed it as an auxiliary

generator in the 1/4 ton 4x4 MB jeep. This generator mounted between

the driver and passenger seats and charged two 6 volt batteries wired

in series that were installed immediately behind each front seat. This

auxiliary generator resided in its own housing and was driven by

a fan belt powered by a full-time PTO mounted on the rear of the jeep

transfer case.

These MB radio jeeps were

manufactured

by Willys throughout WW II and received different model designations

as the jeep itself evolved during the war: the NOM-12, the MZ, MZ-1

and MZ-2. The Auto-Lite 12 volt auxiliary generator was also

available in kit form that could be installed in any standard MB or

GPW jeep to convert it into a non-waterproof 12 volt radio jeep.

These WW II auxiliary generator kits evolved into the postwar

MX-736/MR Power Supply Kit.

|

|

|

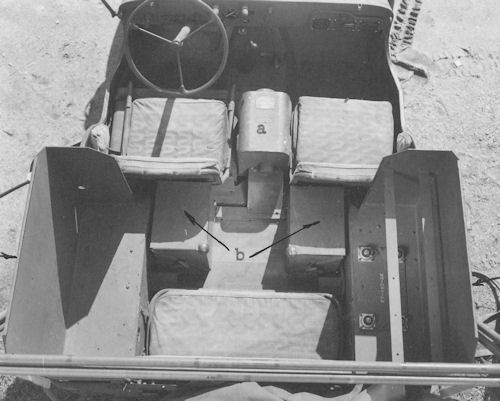

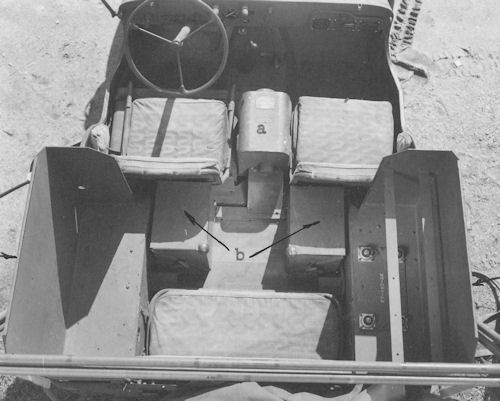

Between the seats generator and

battery boxes. |

Beginning in July 1944, to reduce radio

interference from the jeep’s ignition system, the MZ-2 radio jeep

began using ignition system suppression parts manufactured by Hallett

Engineering, Inc. in Englewood, Calif. The suppression parts were

mostly cast aluminum boxes and housings that fit around standard MB

ignition system parts to restrict transmission of their electrical

signals and static. Although these Hallett aluminum boxes and

casting were tight-fitting, they were not waterproof.

The MZ-2 used the late WW II dustproof

distributor and the standard model W.O. carburetor. The real

challenge will be finding any of the original Hallett ignition

suppression parts that shielded the standard MB ignition system.

Those Hallett parts were removed and discarded either when a Deep

Water Fording kit was installed in the late 1940s or by later owners

if present only to be replaced by standard jeep ignition system

components for which maintenance parts could be found and bought.

Finally, because all Hallett parts were removed when any radio jeep

was upgraded with a postwar waterproof Deep Water Fording kit, very

few Hallett aluminum ignition system suppression parts have survived.

It is very challenging today to find Hallett parts.

As the Pacific campaign unfolded, the

Navy and Marine Corps found they had to waterproof their jeeps in the

field to be able to travel from landing craft to shore with stalling

out or drowning. At their request, Willys in 1943 developed a

partial deep water fording kit contained an exhaust pipe extension

and asbestos goop that was applied to the standard jeep ignition

system to waterproof it. A straight extension pipe going straight up

from the carburetor through a hole in the hood provided the

jeep’s

intake air. But this was only a temporary field fix for a continuing

island invasion problem.

So in January 1945 Willys began

designing the first factory built waterproofed radio jeep called the

MB-Navy Basic (MB-NB). It would have the auxiliary Power Supply kit

and a complete Deep Water Fording Equipment kit installed on the

factory line. Fording equipment included waterproof Auto-Lite ignition

system

components and air intake and exhaust extensions. This jeep

continued using the standard WW II Carter W.O. carburetor that was

waterproofed by having a two-piece aluminum housing installed around

it. That awkward housing continued in use into late 1946.

|

|

|

Waterproof carburetor housing. |

Very

few, if any, MB-NB jeeps were completed or delivered by Willys before

August 15, 1945. The earliest date codes found on any Auto-Lite

waterproof ignition system components are from July and August 1945,

and it seems few, if any, of these waterproof ignition system

components reached the factory production line before WW II ended on

August 15, 1945. It appears only around 300 MB-NB waterproof radio

jeeps were delivered to the Navy after WW II, from August 15, 1945 to

late March 1946. The only Navy/Marine Corps radio jeep produced

from January to July 1945 was the non-waterproof MZ-2. The only

movement towards better deep water performance was one made to its 12

volt 55 ampere auxiliary generator, which was upgraded in

mid-February 1945 to become water-resistant by using brass bushings

in place of steel bushings.

| The waterproof Auto-Lite jeep ignition

system components -- generator, voltage regulator, distributor along

with Champion aircraft spark plugs -- continued to be manufactured

during 1946 and 1947. In late 1947, Willys used many of these

components to produce 1,000 Deep Water Fording kits MX-735/MR for the

Navy. These kits also used the new Carter YS-637S waterproof

carburetor, which replaced the standard WW II Carter model W.O.

carburetor. Many of these 1947 kits were retrofitted on WW II Navy

and Marine Corps radio jeeps to bring them all up to the latest

standards. |

|

|

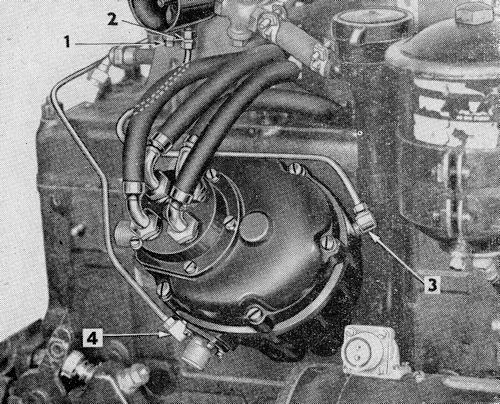

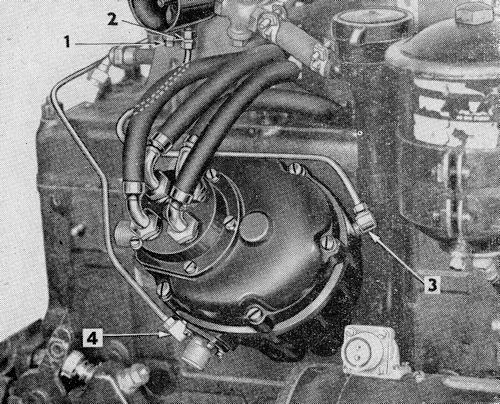

Waterproof Auto-Lite ignition

system. |

| In 1949 Willys revised the Deep Water

Fording to a new standardized kit, MX-735A/MR, by replacing the

Auto-Lite ignition system components with Bendix-Scintilla components

that used fewer connecting cables. Besides being installed in the

field on existing radio jeeps, these new waterproof Deep Water

Fording parts were also installed on the factory production line on

CJ-V35/U jeeps. And in 1952, all remaining Marine Corps radio

jeeps which had not yet had the Bendix-Scintilla ignition system

components installed were ordered to be upgraded with them so they

all shared the latest waterproofing ignition system parts. |

|

|

Bendix-Scintilla distributor with

integral coil. |

For these reasons, today there are only

a few WW II Navy or Marine Corps radio jeeps that have survived in

their original configuration, with just the 12 volt 55 ampere

auxiliary generator between the seats and without having the postwar

waterproof MX-735/MR or MX-735A/MR kits installed along with a mouse

hole cut into their hood.

| Unfortunately for us today, many of

the deep water fording components from either Deep Water Fording kit

(primarily the waterproof distributors and often the YS carburetor)

have been removed over time and replaced with a standard MB/GPW

distributor and model W.O. carburetor to facilitate obtaining

maintenance parts. The YS carburetor was also used on the CJV-35/U

and M38 jeeps so it remains available today. However, the waterproof

ignition system components, whether Auto-Lite or Bendix-Scintilla

brand, are far more difficult to find. Yet some do surface over

time. It just takes patience, persistence and much good luck to find

them. |

|

|

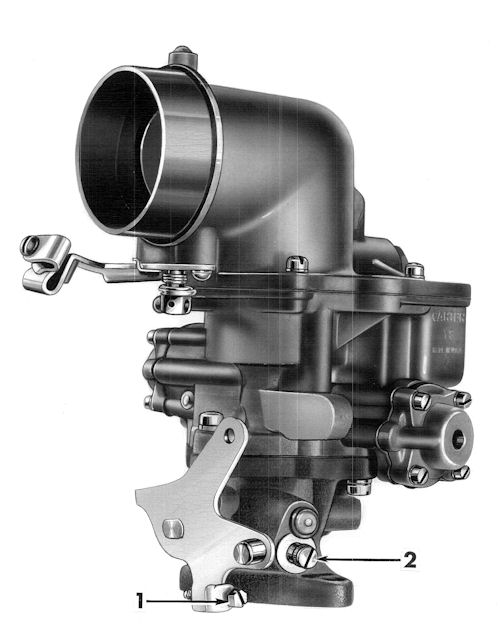

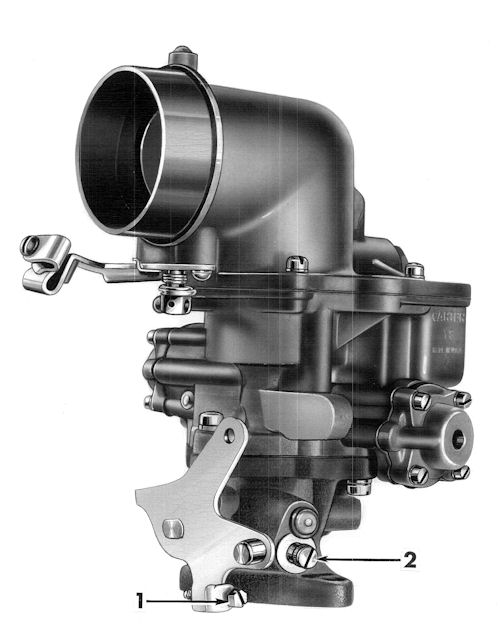

Carter YS-637S waterproof

carburetor. |

The CJ-3A Story | CJ-3A

Photos | CJ-3A Specs and Tech Tips | CJ-3A Literature | Siblings of the CJ-3A | Accessories | Links

www.CJ3A.info © 2013