Home | Site Map | Contact Information

Civilian Jeep Engine

Speed Governors

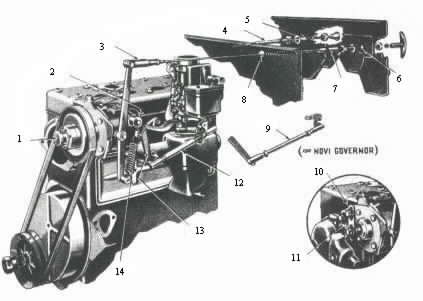

A governor operates like a cruise control; the engine speed is

maintained at a preset value regardless of the load applied. They are

commonly

utilized while running PTO driven equipment. The

controlled

engine speed is set with the hand control mounted on the dash.

With this control at the first notch the controlled engine speed is

1000 rpm. The speed is increased 200 rpm per notch, as the hand

control is pulled out. The top speed is 2600 rpm at the 9th notch. The

hand control is released by turning the handle ¼ turn in either

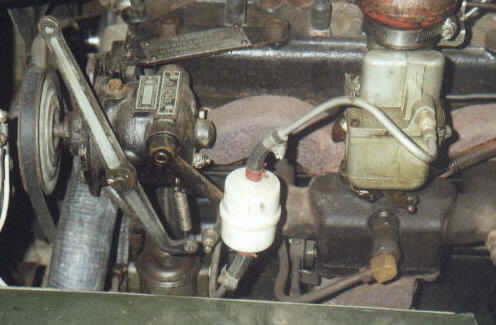

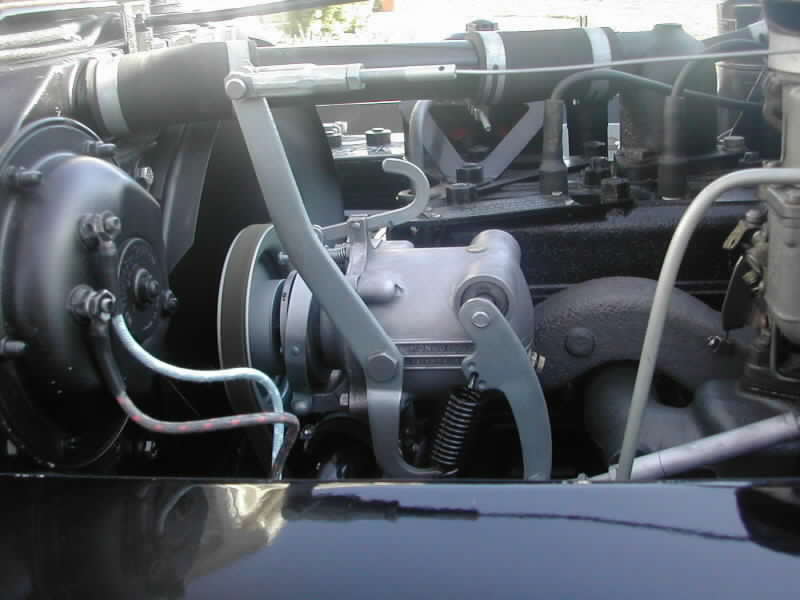

direction. Three different governors are used as standard in

production: the Novi,

the King Seeley

and the Monarch. Other types of governors were used on stationary

equipment, such as generators and compressors. See the photos below to

help identify each governor

type.

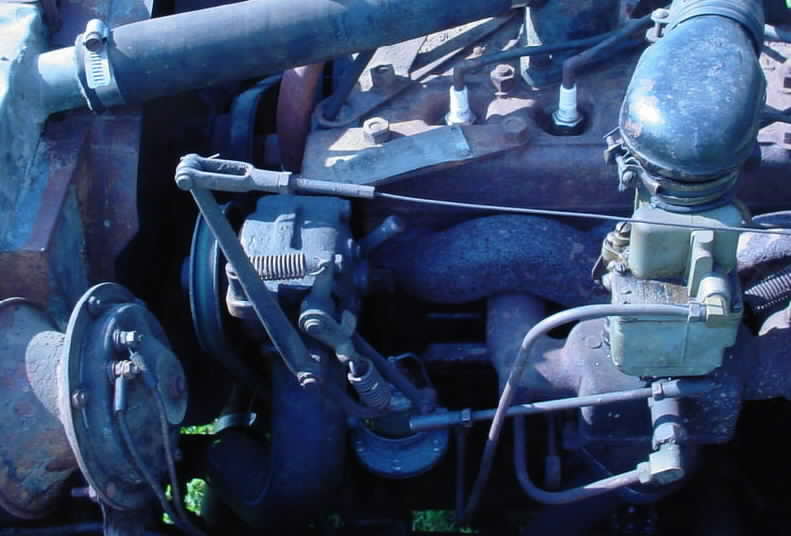

Novi

Governor on a 1948 CJ-2A

Art Contoni photo

The CJ-3A Story | CJ-3A

Photos | CJ-3A Specs and Tech Tips | CJ-3A Literature | Siblings of the CJ-3A | Accessories | Links

cj3a 10/06